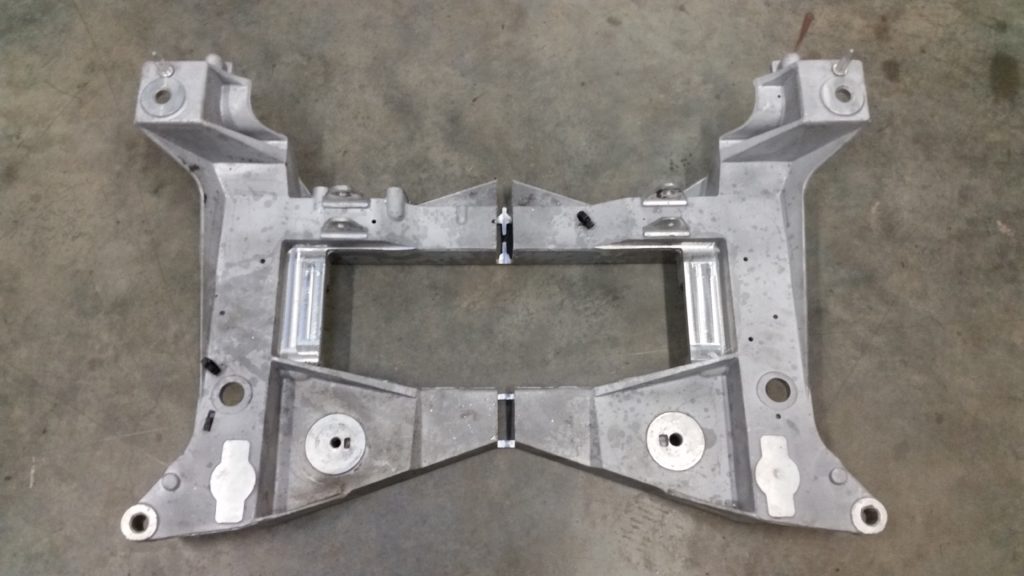

The C5 corvette offers an aluminum lower suspension cradle to house the lower suspension. This makes the C5 suspension available for modification so that you can fit the entire suspension below your favorite body. In a C5 Corvette, the steel chassis frame is the structure to hold the upper control arms. Dobbertin Performance Innovations offers an aluminum precision casting that takes the place of the Corvette frame to hold the upper control arms and provides an easy alternative to designing and recreating the suspension geometry.

The first steps in getting this assembly fitted to your automobile is to get the track width of your car figured out and then compute the difference between your car and the C5. For this project the car will be a 1965 Corvair and the tracking width must be shortened by 7.0 inches. The empty cradle was installed in the milling machine and made level in both X-Y axis. Then the center section of the cradle was lightly machined so that a precision working surface was available instead of the uneven, non-flat surface of the casting. This surface is critical in maintaining the integrity of the suspension geometry and getting the surfaces properly mated again.

Once the center section has been machined, a centerline of the cradle was created and a small 1/2″ slot was machined down the center of the casting separating the two sides. Afterwards each section of the cradle was then set up in the machine so an equal amount of material could be removed from each side of the cradle.

Machine the center line

Remove Equal Amounts of Material

After the two halves of the cradle have been machined it is now time to mate the two sides. This is where the center machining comes into play. On a flat and level surface, the two halves are placed together and the center cradle dimension can be measured between the machined surfaces, left and right. Using 5/8″ flat aluminum plate, a center plate was machined to fit inside the machined area. This plate must be flat and undistorted. This plate will now hold the cradle in proper registration for TIG welding of the two sides. Turning the cradle sections upside down, a 1/2″ hole is drilled through the cradle utilizing the front inverted leaf spring holes. The corners of the 5/8″ plate have been rounded to match the radius of the machined cradle corners so that the aluminum plate mates exactly with the front and side sections of the machined cradle. The 1/2″ holes are then transferred to the aluminum plate and secured to the cradle sections using a 1/2″ bolt and nut. The 5/8″ plate is only used for registration of the cradle sections and to provide added strength, the entire cradle relies on proper TIG welding of the sections once held in registration by the aluminum plate.

Mate the left and right sides and measure the inside cradle dimension

Aluminum plate holds both sides of the cradle in registration for TIG welding

Cradle and upper Dobbertin castings complete the modified C5 suspension

If you have a project in mind and this process is far too complicated for you to complete, feel free to contact us to discuss how we may be able to help. 631-260-9945